Men’s Dress Shirt Fabric Composition & Weaves Types

Fabrics are available in boundless varieties, with equally wide variations in quality. Thus, choosing the right fabric can be an overwhelming process. To enhance your shopping experience with The Libas Store.com and to help you select the perfect fabric for your shirt, we have put together the Fabrics Manual. This manual will help you know what a fabric feels and looks like without actually touching it.

The first step towards understanding fabrics is to understand the various terms used to describe a

fabric:

Composition

Fabrics for a dress shirt can be made of different materials with different compositions, cotton being

the most common. Even cotton can be of different quality that can be measured by its fiber or staple

length. Longer staple lengths mean better quality cotton.

The various types of cotton fabrics offered by The Libas Store are as follows:

| Name | Staple length | Description |

| 100% Cotton | 15-40 mm | Cotton varies according to its fibre and thus, they have varied staple lengths |

| 100% Egyptian cotton | > 40 mm | Egyptian cotton is considered to be one of the world’s finest cottons. Fabrics made of Egyptian cotton are softer, finer and last longer than any other cotton in the world. It is known for its long staples and superior quality which makes it a premier choice for dress shirts. |

| 100% Linen | < 1400 mm | Linen has extremely long fibre lengths and is a very strong material. Good quality linens are generally very smooth to the touch, and often have a slight sheen to them |

| 50% Cotton, 50% Linen | < 1400mm, 15-40mm | Linen blends contain fibres from both the cotton and the flax plant, giving them the properties of both. |

Yarn Characteristics

Sometimes, shirts have a label that says, “80s two ply cotton”. While most people ignore this quality mark, few understand it

s value. This is the description of the yarn used to make the fabric. The feel and comfort of the fabric depends upon the yarn used to weave it. The characteristics of any yarn can be determined by two factors: Ply and Yarn number.

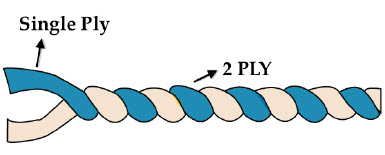

Yarn can be of two types, one ply (single yarn) or two ply  (two yarns twisted together). Fabrics made with two ply yarns are stronger and have a silkier feel to it. In general, fabrics are manufactured with two ply yarn in the warp (length of the fabric, see diagram above) and one ply yarn in the weft (width of the fabric, see diagram above).

(two yarns twisted together). Fabrics made with two ply yarns are stronger and have a silkier feel to it. In general, fabrics are manufactured with two ply yarn in the warp (length of the fabric, see diagram above) and one ply yarn in the weft (width of the fabric, see diagram above).

The next factor to determine the quality of the yarn is the yarn number, also known as the thread count. Often referred to with a number like 80s, 100s or 200s, the yarn number is the thickness of the yarn i.e. the number of hanks (1 hank = 840 yards) of yarn in one pound. A higher yarn number means finer (thinner) yarn.

The next factor to determine the quality of the yarn is the yarn number, also known as the thread

count. Often referred to with a number like 80s, 100s or 200s, the yarn number is the thickness of

the yarn i.e. the number of hanks (1 hank = 840 yards) of yarn in one pound. A higher yarn number

means finer (thinner) yarn.

Note: In terms of thickness, a one ply 50s yarn is the same as a two ply 100s yarn. Therefore, “80s

two ply cotton” would mean that both the warp and the weft are made with two ply yarn that have a

thickness of 80 thread counts.

Colour information

To present correct colours on a computer screen is very difficult and most screens differ substantially from each other. For example, a colour that appears brown on one screen might appear olive green on another. When producing pictures of our fabrics, we use special color calibrated equipment to make the colours look as life-like as possible. However, to avoid matching

errors we always provide information on what colours a fabric contains. These colours mentioned in the product description.

Weave Types

The weave is the way in which the threads of cotton (called warp and weft) are actually put together to make a fabric. Different techniques create different properties in the fabric.

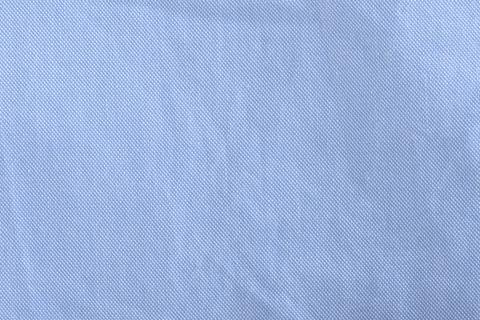

Poplin

Poplin

Poplin, sometimes called broadcloth, is a plain weave which means the threads alternately cross over and then under each other. This results in a very smooth and durable fabric that has an almost silky hand feel, particularly with higher thread counts. Also, poplins look very crisp when ironed.

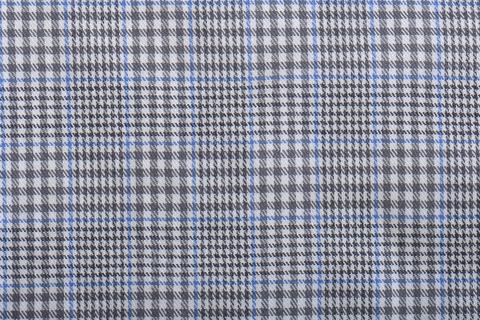

Twill

Twill

Twill fabrics have a weft thread that runs over and under multiple warp threads (as opposed to a plain weave where the weft crosses a single warp thread at a time). This can create interesting patterns like a herringbone, houndstooth or a simple, diagonal rib. Twills are very durable fabrics that have a softer hand feel than poplins and a bit more sheen.

Oxford

Oxford

The traditional oxford is a type of basket weave where multiple weft threads are crossed over an equal number of warp threads. The threads are usually of a single color crossed with a white to give oxford its unique, checkerboard appearance. It’s a versatile fabric that can be worn casually or professionally depending on the thread count and finish.

Dobby

Dobby

The dobby weave is considered a “fancy” weave because dobby weaves generally have unique geometric patterns in the fabric. This is accomplished using a special loom that raises and lowers the warp threads individually, allowing the weaver to create the dobby weave’s distinctive patterns. Dobby fabrics can come in all kinds of patterns, colors, weights and hand feels.

End to End/ Fil-a-Fil

End to End/ Fil-a-Fil

End-on-end fabrics are essentially poplins but with one colored and one white (or other color) thread. This gives the fabric a heathered appearance up close but looks like a solid color from a distance. End-on-ends are sometimes called fil-a-fil from the French for “thread-to-thread” or Chambray.

Herringbone

Herringbone

Herringbone weaves are most often found in wool fabrics and suiting, but it is also found in dress shirting as well. Herringbone weave is a type of twill, and has a distinctive v shaped pattern, named after the herring fish. Herringbone weaves tend to be slightly heavier in weight, and are more often found in seasonal shirting fabrics for cold weather.

Print (Hand Blocked)

Print (Hand Blocked)

While yarn-dyed fabrics are the most common sort of weave for dress shirting, prints are becoming more and more popular. Print fabrics are as they might sound – the pattern is printed onto the fabric, instead of woven by colored thread. Print fabric might be pieced dyed after being woven, and then printed on again. When done by hand, this is known as block printing. Block printed fabrics are most often created by cutting out patterns from wood blocks, which are then dipped in dyes that are pressed in repeated patterns onto fabric. Given the process is done by hand, it is natural to see deviations and slight aberrations in the pattern – which results in a desirable imperfection.

Print (Screen)

Print (Screen)

Screen printing is the most common form of fabric printing, as it allows for a fast transfer of pattern to the fabric. Screens usually produce a much more detailed pattern than hand blocked methods.

Pin-Dot

Pin-Dot

Pin dot fabrics is shorthand for jacquard fabrics that have a raised weave, in consistent patterns. The pattern might be dots, or other geometric shapes.